Updated 01/05/19

Analog to Digital Instrument Cluster Conversion

The following is an instructional document on converting

a Blazer/Jimmy/Bravada/s10 pickup/etc. analog instrument cluster to

the digital instrument cluster.

|

WARNING: THIS DOCUMENT IS TO BE USED AS A GUIDELINE AND THE AUTHOR |

GENERAL INFORMATION

Written by Michael Akey - Copyright 2004. Revision 6.

This document can be reproduced freely as long as it is kept intact and proper recoginition is given to the original author.

BACKGROUND INFORMATION

Some useful information...

This vehicle used in this document is a 1991 Chevrolet Blazer S-10/Tahoe edition with 4 wheel drive and an automatic transmission.

This guide WILL ONLY WORK FOR 1989-1994 MODELS!* If you have an S-10 Blazer that does not fit into that time period, or is a 1994 S-10 pickup, stop reading now. All S-10 Blazers (and equivalent models) made in 1988 and earlier use a cable driven speedometer whereas the newer models receive an electronic signal from a Vehicle Speed Sensor (VSS). Installing a VSS on an older model S-10 Blazer is possible but requires that you find or modify the appropriate DRAC (Digital Ratio Adapter Controller) to match your final drive ratio. This is a little white box mounted next to your ECM. It converts the output of a 40 pole reluctor wheel that takes the place of a speedometer cable and outputs the proper 4000 pulse-per-mile signal needed by the ECM and instrument cluster.

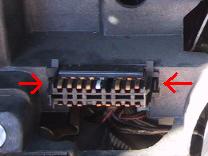

ALL analog instrument clusters use an 18-pin connector that is located in the lower left (looking from the front) of the cluster. Likewise, all digital instrument clusters use the 34-pin connector in the middle of the back of the cluster. GMC Typhoon/Syclone instrument clusters are different and will not be discussed here. It is possible to install a digital cluster in a Typhoon, but you lose your boost gauge.

* Not all 1994 S-10 Pickups are compatible with 1994 Blazer/Jimmy/Bravada clusters. Some are considered "second generation." Also, certain 87-88 model S-10s used an electronic speedometer and you should check your vehicle to be sure. If it is, you can perform this swap.

At least one YouTuber has made a video using these instructions. Thank you to them for linking to my page in the description. The video is located here: https://www.youtube.com/watch?v=X8-N4PsqfMQ, and may be helpful for those more visually inclined. When I first did this conversion YouTube didn't exist and since then I have moved on to a different vehicle. You are welcome to ask me questions and I will help as I can. See the bottom of the page for contact information. It is still pretty crazy to me that after 15+ years people are still referencing this page and asking questions. I've tried to answer common questions by updating this page but I still get a challenge now and then. Thanks for reading and I hope this page is helpful.

MATERIALS

These are some of the required materials and tools. You may use others at your discretion.

THE CONNECTORS

The 18-pin connector:

The Pinout:

| 1 | Panel lamp input | 10 | Anti-Lock indicator lamp |

| 2 | Hot (+12V) | 11 | Service Engine Soon indicator lamp |

| 3 | Generator indicator lamp | 12 | Hot (+12V from generator) |

| 4 | Upshift | 13 | DRL indicator |

| 5 | E. Brake light | 14 | Speedometer input |

| 6 | Coolant temp. input | 15 | Fasten seat belts lamp |

| 7 | right turn signal | 16 | High-Beam indicator lamp |

| 8 | Fuel sensor input | 17 | Ground |

| 9 | Oil pressure input | 18 | Left turn signal |

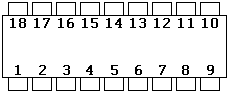

The 34-pin connector:

CLUSTER REMOVAL

The following are the instructions on how to remove the Instrument Cluster. Remember to store screws in a safe place.

Step 1:

Remove the fuse cover panel under the steering column.

Step 2:

Remove the bottom plate by taking out the bolt above the gas pedal and the 3 screws holding it on. The 3 screws can be removed by a flat head screw driver or a 9/32in. nut driver.

Step 3:

Remove the 2 screws that hold on the AL/DL connector to the bottom plate.

Step 4:

Remove all screws holding on the under steering column trim plate. Don't forget to remove the Parking Brake screw. To fully remove the trim, one must remove the ventilation tube and Parking Brake cable. To remove the Parking Break cable, use a flat head screw driver to compress the spring on the end of the cable and push the lever it is connected to towards the rear of the vehicle. It is helpful to disengage the parking brake to remove the handle - Only do so after blocking the wheels so the vehicle will not move while you're working on it!

Step 5:

Remove the lighting controls plate. Be careful when removing the connectors from the switches -- they break easily. WARNING: light switches ALWAYS have power running to them.

Step 6:

Loosen the Air conditioning vacuum hoses.

Step 7:

Remove A/C control plate screws.

Step 8:

Disconnect the blower switch cable, and grey wires. Then gently pull on the entire assembly until it is about 6 inches out. This should allow plently of space for the next step. If you must remove the assembly completely, pop off the clamps holding the temperature selector switch and vacuum hoses. However this is not recommended as it is easy to break the plastic pins. It may be possible to only remove the bezel of the selector switch with a nut driver and removing the selector switch tabs (the exposed part that your fingers use to manipulate the controls). This would enable the whole vacuum assembly to be slid through the dash bezel once it is freed in a later step.

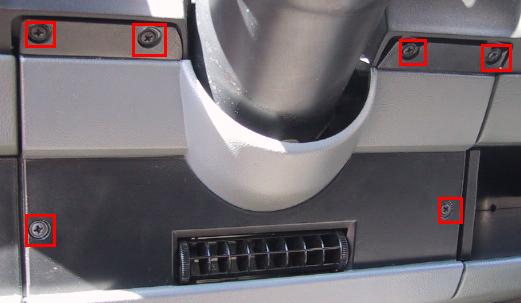

Step 9:

Remove the 4 bolts that hold on the bezel. (two more nuts on the opposite side; use 10mm nut driver) You may want a "magnetic wand" or some kind to hold on/fetch the bolt so you don't lose it (don't worry, it won't go far anyway.)

Step 10:

Pull out bezel and flip to it's side so it is out of the way.

Step 11:

Remove the 4 fake nuts that are holding the cluster in.

Step 12:

Gently pull cluster out. Removing the analog cluster can be difficult given the angle of the bolts in the dash and the lack of slop in the cluster's mounting holes. On the other hand, the digital cluster's mounting holes have ample space for easy installation and removal. Don't forget to detach the shifter cable from the steering column if you have an automatic transmission!

Hi-res picture of the analog cluster from the back.

OK! You're done. If you want to put it back together, just perform the removal steps in reverse order!

CONVERSION

NOW WOULD BE A GOOD TIME TO DISCONNECT THE NEGATIVE TERMINAL OF THE BATTERY!

Since most people do not have computers with internet access in their garages, printing out the wiring charts out might be a wise idea.

Step 1:

After the old cluster is removed and out of the way, unclip the 18-pin connector by pressing in on the 2 tabs (see below)

Step 2a:

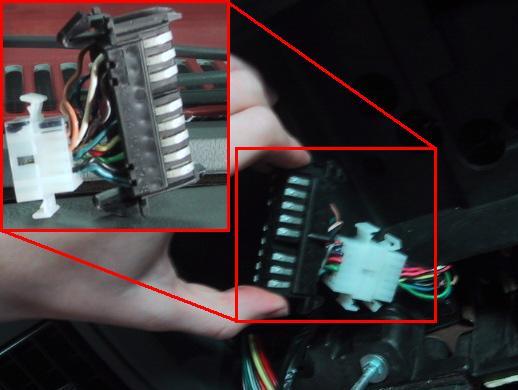

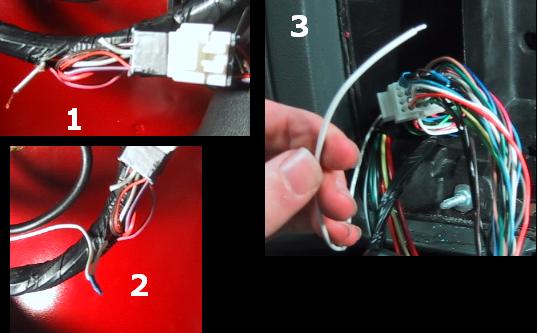

There are many ways to do this step. This is also the longest and most crucial step, so take your time. Attach the new 34-pin connector to the old 18-pin connector using the wiring chart below. The method shown in the following pictures is jsut one way to do this. You can just connect all the wires up after clipping off the old 18-pin connector, make a connector (like shown) so you can revert back to the analog cluster, or how ever you choose. DO NOT REASSEMBLE DASH IMMEDIATELY AFTER COMPLETING THIS PROCESS.

This table shows where the pins on the 34-pin connector connect to the 18-pin connector.

| 1 | 6 | 18 | 2 |

| 2 | 9 | 19 | same as 18 |

| 3 | n/a | 20 | n/a |

| 4 | see below | 21 | cig. outlet (orange) |

| 5 | n/a | 22 | n/a |

| 6 | 17(see below) | 23 | n/a |

| 7 | 7 | 24 | 17 |

| 8 | 18 | 25 | n/a |

| 9 | 17 | 26 | n/a |

| 10 | 3 | 27 | n/a |

| 11 | 14 | 28 | n/a |

| 12 | 8 | 29 | never used? |

| 13 | 1 | 30 | not implemented |

| 14 | 11 | 31 | 4 |

| 15 | 12 | 32 | 13 |

| 16 | 5 | 33 | 10 |

| 17 | 15 | 34 | 16 |

INFO: wire number 21 from the digtal cluster does not need to be hooked up to a constant power source on 91-94 models. 89-90 are required to have this hooked up to an always hot source such as the cig outlet. This is to keep the trip data while your car is off.

MORE INFO: Pin 6 is for the dimming of the gauges while your headlights are on. If you don't want them to dim, just ground the wire. If you do want them to dim, wire it into the dark brown wire that goes to your dimmer switch on your lights panel on the left of the bezel.

Conversion using a middle connector to allow usage of both analog and digital clusters(more time consuming.)

Step 2b:

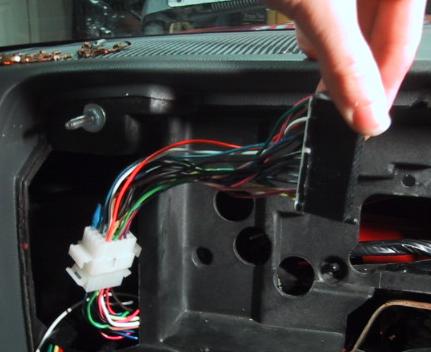

Before the connector can be fully installed, the tachometer must be wired in. To do this, remove the lower panel under the dash on the passenger side. Removing the floor shifter cover will make removing this panel much easier.

Now pull back the carpet as shown, and gently bring down the ECM wiring harness. Look for the white connector taped to the harness. Find the solid white wire going into it. If you had a digital insturment cluster factory installed, this wire would pass through the connector and go to your instrument cluster. Cut into that wire and use some 16 or 18 gauge wire and route it to the instrument cluster connector.

Step 3:

The next thing to do is to plug in your connector to the digital cluster to make sure it works. Start the car and make sure the tach also works. Once you have confirmed that everything is in order, continue on. NOTE: When there is no signal to the oil/fuel gauges, they will read as max/full.

Example photos:

Power On Self Test

Display on, engine off

Engine running

Step 4:

To finalize the process, you now have to slide the connector into the plastic connector holder, shown below. Then carefully push it back into the dash so that the 3 screw holes are behind the plastic of the dash (see below). You may need to remove one of the wiring harness clips that occupy the hole where the bottom screw goes. How you attach the plastic holder is up to you, but remember to watch out for the wiring harness. You do NOT want to accidentally put a screw into that -- this would cause serious damage to your electrical system. I personally when to the hardware store and picked up some new screws and bolts that were about a half inch long, and some washers to hold the screws in on the back side.

Step 5:

Install the cluster making sure to put the shifter cable through the hole (see below). DO NOT FORCE IT. You may need to re-align the rear 34-pin connector so that it fits properly.

Step 6:

Check and make sure the cluster works once more, and then take the car our for a spin and make sure the speedometer works. Then put everything back together and you're done! Please feel free to email me with questions using the email at the bottom of the page.

FREQUENTLY ASKED QUESTIONS and EXTRA INFORMATION

Where can I get the white connectors you used for an intermediate connector (pictured below step 2a)?

These are Molex connectors, Digi-Key as well as many other electronics parts vendors have them available. (Part on Digi-Key, Molex part number 76650-0071)

What if my digital gauges do not work properly?

I don't repair them -- however, other people do (Some are on eBay). Also http://www.mrwhizard.com/ repairs them and will ship to Canada. Please note I have never used their services. Any repairs needed for gauges that I've used or tested were done by myself. Often times it's just bad solder joints on the power supply daughterboard, or the tubes themselves. I've heard that the Vacuum Fluorescent Display drive supply was rather wimpy and would die prematurely, but I have not run into this personally.

Thanks for visiting!

Are there different types for different vehicles?

Yes. There are some subtle differences, but are mainly cosmetic:

Anything else?

The tachometer is very low resolution. The first 3 bars are wired together, and the higer the scale, it only goes in increments of 500RPM. Also, the VFD has "V6" after the word "TACHOMETER," but it was never wired up. The gauges can be modified to work with a V8, and it requires modifying the frequency-to-voltage converter on the blue back-board of the cluster. I have never needed to do this, but it's possible.